Introduction

Surface Mount Technology (SMT) equipment is the backbone of modern electronics manufacturing. By allowing components to be mounted directly onto printed circuit boards (PCBs), SMT revolutionized the way electronic devices are designed and produced. Today, everything from smartphones and laptops to automobiles and medical equipment relies on SMT to achieve compact designs, efficient performance, and scalable production.

The global SMT equipment market has gained immense importance in the era of digitization, automation, and connected devices. With demand for electronics rising across consumer, industrial, automotive, and healthcare sectors, the role of SMT equipment in enabling innovation has become indispensable. As manufacturers transition toward Industry 4.0 practices, SMT is at the center of this transformation, integrating robotics, artificial intelligence, and smart analytics into production lines.

This report explores the dynamics of the SMT equipment market, examining key drivers, restraints, segmentation patterns, competitive strategies, and future opportunities. It provides valuable insights for stakeholders ranging from manufacturers and suppliers to investors and policymakers.

Market Overview

Surface Mount Technology refers to the process of mounting electronic components directly onto the surface of PCBs, replacing traditional through-hole methods. SMT equipment includes placement machines, soldering equipment, inspection systems, screen printers, and rework stations. These tools collectively create highly automated and precise assembly lines capable of handling miniature components with speed and accuracy.

Historically, SMT gained traction in the 1980s as the electronics industry sought more compact and efficient ways to assemble PCBs. Over time, SMT displaced conventional assembly techniques due to its superior density, reliability, and scalability. In today’s market, SMT is the dominant method of electronics assembly, serving high-volume applications in consumer electronics, automotive electronics, telecommunications, and industrial automation.

The market is characterized by steady growth, fueled by the increasing penetration of advanced electronics and rising demand for miniaturization. Countries with strong electronics manufacturing hubs, such as those in East Asia, continue to lead in SMT adoption. Meanwhile, regions like North America and Europe maintain strong shares through high-value applications in aerospace, defense, and healthcare.

Market Drivers and Opportunities

The SMT equipment market is supported by a wide range of growth drivers.

One of the most important factors is the global boom in consumer electronics. With billions of smartphones, wearables, tablets, and home automation devices shipped annually, manufacturers require highly efficient SMT systems to meet production demands. Miniaturization trends have also pushed the adoption of SMT equipment, as traditional assembly methods cannot accommodate the small component sizes now common in advanced devices.

The automotive industry is another critical driver. As electric vehicles, driver assistance systems, and infotainment platforms become standard, cars are evolving into electronic systems on wheels. This transformation creates enormous opportunities for SMT equipment providers, particularly in advanced PCB assembly and reliability testing.

Industrial automation and the rollout of 5G infrastructure also provide opportunities. Telecom companies are investing heavily in base stations, servers, and networking hardware, all of which rely on high-performance PCBs manufactured with SMT. Similarly, industrial automation systems, smart factories, and robotics demand highly integrated electronic solutions, further expanding the market.

Emerging opportunities exist in artificial intelligence integration, predictive maintenance, and cloud-based analytics for SMT equipment. As manufacturers move toward fully connected smart factories, SMT systems equipped with sensors and AI will enable real-time monitoring and process optimization, reducing downtime and improving yields.

Market Challenges and Restraints

While the market outlook is positive, SMT equipment providers face several challenges.

The high cost of advanced SMT machines can limit adoption among small and medium-sized manufacturers. These systems require significant upfront investment, making them less accessible in price-sensitive regions.

Another challenge lies in the complexity of SMT assembly processes. As components continue to shrink and device designs grow more sophisticated, equipment must maintain extremely high precision and accuracy. This requires constant innovation and upgrades, which can strain resources for both manufacturers and end-users.

Supply chain disruptions also pose risks. The electronics industry is highly globalized, relying on suppliers spread across multiple regions. Shortages of semiconductors, raw materials, or key equipment parts can significantly slow production. Additionally, geopolitical tensions and trade restrictions can further disrupt supply flows.

Regulatory pressures related to sustainability and environmental standards present another restraint. SMT equipment manufacturers must adapt to stricter rules on energy efficiency, emissions, and hazardous materials, particularly in regions with stringent compliance requirements.

Market Segmentation Analysis

The SMT equipment market can be segmented by product type, application, distribution channel, and geography.

By product type, placement machines represent the largest share, as they are the core equipment responsible for accurately placing components on PCBs. Soldering equipment and reflow ovens are equally critical, ensuring secure bonding and electrical conductivity. Inspection equipment, including automated optical inspection (AOI) and X-ray systems, is growing rapidly as manufacturers prioritize defect detection and quality assurance. Screen printers and rework systems complete the ecosystem, offering flexibility and support for both high-volume and specialized production runs.

In terms of applications, consumer electronics dominate the market due to the sheer scale of demand for mobile devices, personal gadgets, and household electronics. The automotive segment is emerging as one of the fastest-growing categories, driven by electric vehicles and autonomous driving technologies. Industrial applications, including robotics, automation, and smart energy systems, represent another growing area. Healthcare and aerospace also contribute significantly, with high-value, precision-driven applications.

Distribution channels are shifting as well. While direct sales and long-term partnerships with major manufacturers remain important, distributors and value-added resellers are expanding their role, particularly in serving mid-sized and small enterprises.

Regionally, East Asia holds the largest share of the SMT equipment market, driven by the concentration of electronics manufacturing in countries such as China, Japan, South Korea, and Taiwan. North America and Europe remain significant players, particularly in high-value applications requiring stringent quality standards. Emerging regions in Southeast Asia, Latin America, and the Middle East are showing potential as electronics demand spreads globally.

Competitive Landscape

The SMT equipment market is moderately consolidated, with a mix of global leaders and specialized regional players. Key companies provide comprehensive portfolios of placement machines, soldering solutions, and inspection systems, while also investing in software platforms to enable smart manufacturing.

Large multinational corporations have established strong global footprints, supported by advanced R&D capabilities and extensive distribution networks. These firms compete on innovation, speed, precision, and integration with digital technologies. Partnerships with electronics manufacturers, acquisitions of smaller technology providers, and collaborations with research institutions are common strategies to stay ahead.

Emerging players often focus on niche innovations, such as AI-driven inspection systems or compact machines suited for mid-sized manufacturers. This diversity fosters healthy competition and continuous technological advancement within the industry.

Overall, the competitive environment emphasizes innovation, customer support, and cost efficiency as manufacturers seek to balance performance with affordability.

Future Outlook and Trends

The future of the SMT equipment market is strongly tied to the evolution of global electronics manufacturing. Over the next decade, demand for miniaturization, automation, and digital connectivity will continue to grow.

Smart factories represent a major trend. SMT equipment integrated with IoT sensors, AI-driven monitoring, and predictive maintenance systems will redefine efficiency by enabling real-time data insights and self-optimizing production lines. Sustainability will also be a key focus, with energy-efficient machines and eco-friendly materials shaping purchasing decisions.

The automotive industry is expected to be a leading driver, particularly with the rise of electric vehicles and autonomous technologies. Similarly, the ongoing expansion of 5G infrastructure and next-generation communication technologies will ensure strong demand for advanced PCBs and high-performance assembly systems.

Emerging markets will play a greater role, as governments invest in electronics manufacturing hubs and offer incentives to attract global players. While North America and Europe will continue to dominate high-value segments, Asia-Pacific will maintain its position as the world’s largest manufacturing base.

Conclusion

The Surface Mount Technology equipment market stands at the heart of the global electronics revolution. With applications spanning consumer electronics, automotive, industrial automation, and healthcare, SMT has become an indispensable enabler of innovation and progress.

Although the industry faces challenges such as high costs, supply chain disruptions, and regulatory pressures, its long-term outlook remains highly favorable. Companies that embrace automation, integrate digital technologies, and expand into emerging markets are well-positioned to thrive in this evolving landscape.

For stakeholders across the value chain, the SMT equipment market offers a wealth of opportunities, combining stability with innovation-driven growth.

Frequently Asked Questions

What is the current size of the SMT equipment market?

The market is steadily expanding, supported by strong demand from consumer electronics, automotive, and industrial sectors. It represents a multi-billion-dollar industry with consistent growth over recent years.

What are the key drivers influencing growth in this market?

Key drivers include the rising demand for miniaturized electronics, the boom in consumer devices, growth in electric vehicles, and the adoption of Industry 4.0 practices such as automation and AI integration.

Which regions dominate the SMT equipment market?

East Asia is the leading region due to its concentration of electronics manufacturing. North America and Europe remain important for high-value applications, while emerging regions in Southeast Asia and Latin America are gaining momentum.

Who are the major players in the industry?

The market includes large multinational corporations specializing in placement machines, soldering systems, and inspection equipment. Alongside these leaders, niche players provide innovative solutions tailored to smaller manufacturers and specialized applications.

What are the latest trends shaping the future of this market?

Major trends include the rise of smart factories, integration of AI and IoT in SMT equipment, the focus on energy efficiency and sustainability, and the growing role of electric vehicles in driving electronics demand.

What challenges could slow down growth in this sector?

Challenges include the high cost of equipment, complexity in managing miniaturized components, supply chain disruptions, and regulatory pressures related to sustainability and compliance.

How can businesses benefit from investing in the SMT equipment market?

Businesses can benefit by adopting advanced SMT solutions to improve efficiency, reduce defects, and meet the rising demand for sophisticated electronics. Companies that align with digital transformation, sustainability, and global expansion strategies are particularly well-positioned for long-term success.

Browse More Reports:

Global Parenteral Nutrition Market

Global Pharmaceutical Packaging Market

Global Phosphoric Acid Market

Global Premium Chocolate Market

Australia Pro AV (Audio-Visual) Market

Global Bitumen Market

Global Egg Powder Market

Global Emission Monitoring System Market

Global Lidocaine Market

Global Loitering Munition Market

Global Medical Gas Market

Global Nitrogen, Phosphorus and Potassium (NPK) Fertilizers Market

Global Radar Market

Global Surface Mount Technology (SMT) Equipment Market

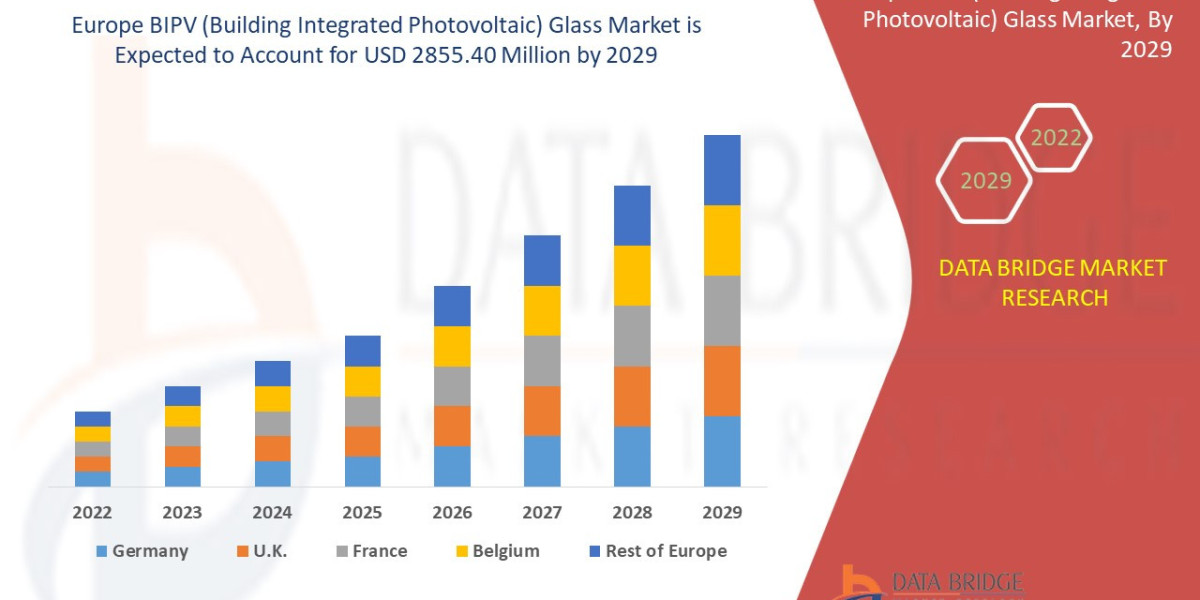

Europe BIPV (Building Integrated Photovoltaic) Glass Market

Saudi Arabia Bitumen Market

Asia-Pacific Business Process Outsourcing (BPO) Market

Middle East and Africa Business Process Outsourcing (BPO) Market

North America Business Process Outsourcing (BPO) Market

U.A.E. Business Process Outsourcing (BPO) Market

About Data Bridge Market Research:

An absolute way to forecast what the future holds is to comprehend the trend today!

Data Bridge Market Research set forth itself as an unconventional and neoteric market research and consulting firm with an unparalleled level of resilience and integrated approaches. We are determined to unearth the best market opportunities and foster efficient information for your business to thrive in the market. Data Bridge endeavors to provide appropriate solutions to the complex business challenges and initiates an effortless decision-making process. Data Bridge is an aftermath of sheer wisdom and experience which was formulated and framed in the year 2015 in Pune.

Contact Us:

Data Bridge Market Research

US: +1 614 591 3140

UK: +44 845 154 9652

APAC : +653 1251 975

Email:- corporatesales@databridgemarketresearch.com