The Ultra High Temperature Ceramics (UHTC) Market is rapidly gaining momentum as industries seek advanced materials capable of withstanding extreme conditions. UHTCs, known for their exceptional thermal resistance (above 2000°C), are becoming indispensable in aerospace, defense, and hypersonic vehicle development. With innovations in material science and manufacturing processes, the market is set for transformative growth over the next decade.

These ceramics, primarily composed of borides, carbides, and nitrides of transition metals, deliver unmatched hardness, oxidation resistance, and thermal stability. Their ability to endure harsh environments makes them ideal for leading-edge applications such as rocket nozzles, re-entry vehicle surfaces, nuclear reactors, and turbine components.

According to Dataintelo, the Ultra High Temperature Ceramics (UHTC) Market is expected to grow significantly through 2032, driven by defense modernization efforts, hypersonic research initiatives, and increasing demand for high-performance thermal materials across industrial sectors.

Request a Sample Report:

https://dataintelo.com/request-sample/183879

Key Market Drivers

Surging Demand in Aerospace & Defense: Government investments in hypersonic weapons, reusable spacecraft, and missile defense systems are intensifying the demand for UHTCs, especially in North America, Europe, and Asia-Pacific.

Thermal Management in Energy Systems: The push for efficient thermal barrier systems in nuclear and high-temperature industrial processes is enhancing UHTC adoption.

Advancements in Additive Manufacturing: Breakthroughs in 3D printing of ceramics are opening up new design possibilities, reducing costs, and enabling complex geometries in UHTC-based components.

Market Restraints

High Processing Costs: The complexity and energy-intensive nature of producing UHTCs limit widespread adoption, especially in cost-sensitive industries.

Brittleness and Design Constraints: Despite their thermal advantages, UHTCs tend to be brittle, posing challenges in mechanical applications that require toughness and flexibility.

Limited Commercial Awareness: Outside of specialized industries, the full potential of UHTCs is yet to be recognized, curbing their adoption in emerging sectors.

View Full Report:

https://dataintelo.com/report/global-ultra-high-temperature-ceramics-uhtc-market

Emerging Opportunities

Hypersonic Vehicle Development: Countries developing next-generation hypersonic technologies are fueling the demand for UHTCs in leading-edge materials for thermal protection systems.

Clean Energy Technologies: UHTCs offer promising applications in concentrated solar power (CSP) systems, where extreme thermal resistance is crucial for efficient energy conversion.

Additive Manufacturing Scale-Up: Commercialization of UHTC-compatible additive manufacturing techniques could lower barriers to entry and accelerate adoption across industries.

Market Dynamics and Growth Forecast

The global Ultra High Temperature Ceramics (UHTC) Market was valued at USD 605 million in 2023 and is projected to reach approximately USD 1.15 billion by 2032, expanding at a CAGR of 7.3% over the forecast period. This growth is driven by expanding end-user applications and ongoing R&D in materials science and thermal coatings.

Regional insights:

North America leads the market with a strong presence of aerospace R&D facilities and defense contractors.

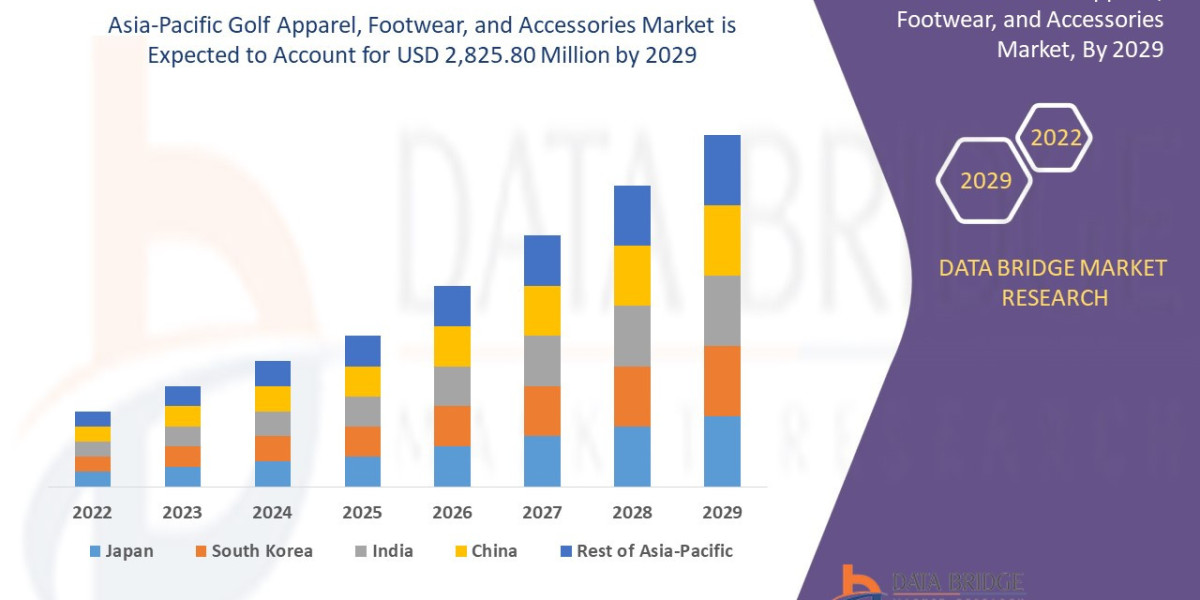

Asia-Pacific is anticipated to exhibit the fastest growth, fueled by aggressive defense spending and rapid industrialization in countries like China, India, and South Korea.

Europe remains a crucial hub due to investments in advanced manufacturing and clean energy systems.

Check Out the Report:

https://dataintelo.com/checkout/183879

Market Segmentation Overview

The Ultra High Temperature Ceramics (UHTC) Market is segmented by material type, application, and end-user industry:

By Material Type:

Zirconium Diboride (ZrB₂)

Hafnium Diboride (HfB₂)

Tantalum Carbide (TaC)

Others (including HfC, ZrC)

By Application:

Thermal Protection Systems

Aerospace Components

Industrial Furnaces

Nuclear Applications

By End-User Industry:

Aerospace & Defense

Energy & Power

Industrial Manufacturing

Research Institutes

Zirconium Diboride (ZrB₂) holds the largest market share due to its excellent thermal conductivity and oxidation resistance, followed closely by Hafnium Diboride (HfB₂), valued for ultra-high melting points and mechanical strength.

Industry Trends and Technological Advancements

Rising Government R&D Initiatives: Several countries are investing in national research programs to develop next-gen thermal shielding technologies, increasing collaboration between academia and industry.

Nanostructured UHTCs: Research into nano-engineered UHTCs is leading to materials with improved fracture toughness, surface finish, and oxidation behavior.

Sustainable Manufacturing Methods: Industry players are exploring eco-friendly production methods, including low-energy sintering and green precursors, to reduce environmental impact.

Strategic Implications and Market Outlook

As global industries face growing demand for high-efficiency, high-temperature performance, UHTCs are becoming a strategic material choice. Their application in mission-critical systems is no longer optional but essential. While challenges such as brittleness and cost persist, the rising volume of investment in R&D and manufacturing technologies is expected to address these hurdles in the near term.

In particular, space exploration, military aerospace, and industrial process equipment will remain at the forefront of demand. Additionally, the integration of UHTCs into energy systems and chemical reactors could unlock new revenue streams for manufacturers and material scientists alike.

Final Thoughts

The Ultra High Temperature Ceramics (UHTC) Market is evolving into a critical pillar of high-performance materials, with applications extending from space missions to nuclear reactors. As technological barriers are overcome and awareness spreads across sectors, the market is poised for long-term, sustainable growth.

For stakeholders across defense, energy, aerospace, and manufacturing sectors, now is the time to explore the potential of UHTCs. With promising developments in material design and fabrication methods, UHTCs represent the next frontier in high-temperature engineering solutions.