"Executive Summary Automotive Plastics for Electrical Vehicle Market :

"Executive Summary Automotive Plastics for Electrical Vehicle Market :

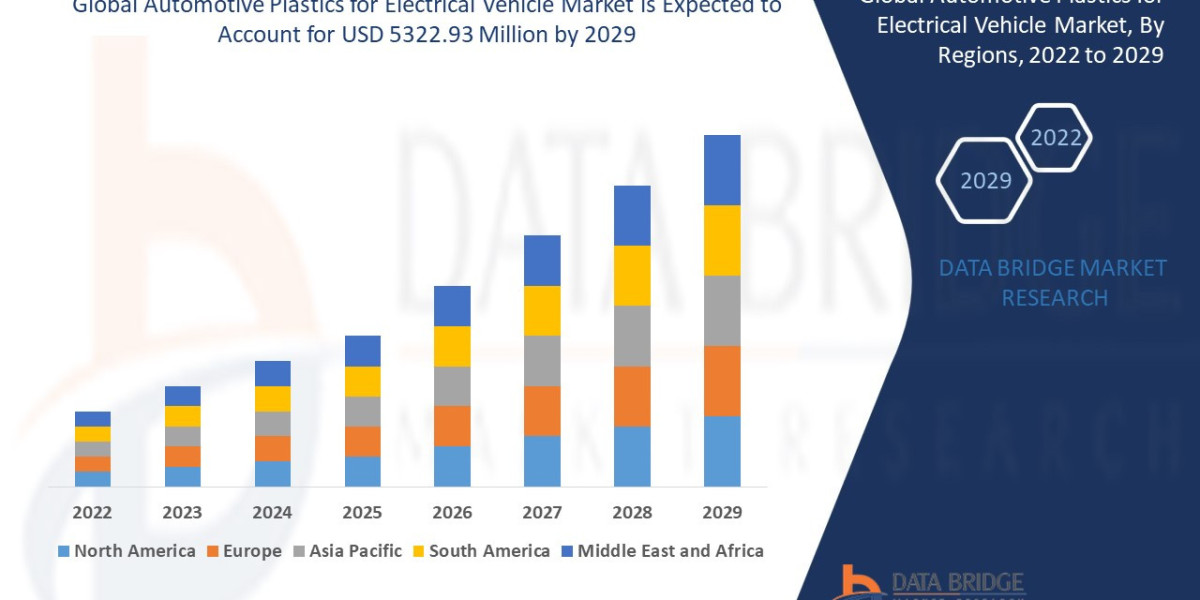

Data Bridge Market Research analyses that the automotive plastics for electrical vehicle market is expected to undergo a CAGR of 27.40% during the forecast period.

All the data and information mentioned in this Automotive Plastics for Electrical Vehicle Market report assists businesses take superior decisions and improve return on investment (ROI). The market status, growth rate, future trends, market drivers, opportunities and challenges, risks and entry barriers, sales channels, distributors and Porter's Five Forces Analysis has been analysed in this Automotive Plastics for Electrical Vehicle Market research report. Different types of charts and graphs are used in the report wherever applicable for the better understanding of complex information and data. A thoughtful knowledge of industrial unanimity, market trends and implausible techniques makes clients gain an upper hand in the market.

This Automotive Plastics for Electrical Vehicle Market report is also enriched with a range of factors that have an influence on the market and industry which includes industry insight and critical success factors (CSFs), market segmentation and value chain analysis, industry dynamics, drivers, restraints, key opportunities, technology and application outlook, country-level and regional analysis, competitive landscape, company market share analysis and key company profiles. Be it about considering public demands, competencies and the constant growth of the working industry, vibrant reporting, or about high data protection services, this report has everything summed up together. For better understanding of the market and leading business growth, Automotive Plastics for Electrical Vehicle Market research report is the superlative solution.

Discover the latest trends, growth opportunities, and strategic insights in our comprehensive Automotive Plastics for Electrical Vehicle Market report. Download Full Report: https://www.databridgemarketresearch.com/reports/global-automotive-plastics-for-electrical-vehicle-market

Automotive Plastics for Electrical Vehicle Market Overview

**Segments**

- **By Product Type:** On the basis of product type, the global automotive plastics for electrical vehicle market can be segmented into polypropylene, polyurethane, PVC, polyethylene, ABS, polycarbonate, and others. Polypropylene is one of the most commonly used plastics in automotive applications due to its lightweight and high strength properties. Polyurethane is also gaining popularity in the market as it offers excellent resistance to abrasion and chemicals. PVC is widely used in interior components of electric vehicles for its durability and cost-effectiveness.

- **By Application:** The market can be segmented by application into powertrain, interior, exterior, and other components. Powertrain components such as battery casings and electric motor housings require durable and heat-resistant plastics like polycarbonate and ABS. Interior components like dashboards and door panels often utilize polypropylene and PVC for their lightweight and aesthetic properties. Exterior components such as bumpers and body panels require impact-resistant plastics like polyurethane and polyethylene.

- **By Vehicle Type:** Based on vehicle type, the market can be segmented into passenger cars, commercial vehicles, and electric bikes. Passenger cars account for a significant share in the market due to the growing demand for electric vehicles among consumers. Commercial vehicles are also adopting automotive plastics for electrical vehicles to improve fuel efficiency and reduce emissions. Electric bikes use plastics for lightweight and corrosion resistance.

**Market Players**

- **BASF SE:** BASF is a leading player in the global automotive plastics market, offering a wide range of innovative solutions for electrical vehicles. The company focuses on developing sustainable plastics that meet the stringent requirements of the automotive industry.

- **Covestro AG:** Covestro is another key player in the market, known for its high-performance materials such as polycarbonates and polyurethanes. The company collaborates with automotive manufacturers to develop lightweight and durable solutions for electric vehicles.

- **SABIC:** SABIC is a major supplier of automotive plastics, providing materials like polypropylene and ABS for electrical vehicle applications. The company emphasizes on developing eco-friendly plastics to support the shift towards sustainable transportation.

- **DuPont:** DuPont offers a broad portfolio of specialty plastics for the automotive sector, including materials for electric vehicle components. The company focuses on enhancing the performance and efficiency of electric vehicles through its innovative solutions.

- **Evonik Industries:** Evonik specializes in high-performance plastics for electrical vehicles, catering to the growing demand for lightweight and durable materials in the automotive industry. The company's focus on sustainability and innovation drives its presence in the market.

The global automotive plastics for electrical vehicles market is experiencing significant growth driven by the increasing adoption of electric vehicles worldwide. The shift towards electric mobility is fueling the demand for lightweight, durable, and eco-friendly plastics in the automotive industry. Manufacturers are focusing on developing innovative solutions to meet the stringent requirements of electric vehicle components, including powertrain, interior, and exterior parts. Polypropylene, polyurethane, PVC, ABS, and polycarbonate are among the key plastics being used in electric vehicles for their unique properties such as lightweight, high strength, resistance to abrasion, and durability.

In terms of applications, powertrain components like battery casings and electric motor housings require heat-resistant plastics such as polycarbonate and ABS to ensure durability and performance. Interior components such as dashboards and door panels utilize lightweight plastics like polypropylene and PVC for aesthetic appeal and cost-effectiveness. Exterior components including bumpers and body panels need impact-resistant materials like polyurethane and polyethylene to withstand harsh environmental conditions. The segmentation by application highlights the diverse range of automotive plastics used in electric vehicles to enhance functionality and efficiency.

When considering vehicle types, passenger cars are leading the adoption of automotive plastics for electrical vehicles due to increasing consumer demand for electric mobility solutions. Commercial vehicles are also incorporating advanced plastics to improve fuel efficiency and reduce emissions in line with stringent environmental regulations. Electric bikes are utilizing plastics for their lightweight and corrosion-resistant properties, catering to the growing market for eco-friendly two-wheeled vehicles. The segmentation by vehicle type demonstrates the widespread application of automotive plastics across different categories of electric vehicles.

Key market players such as BASF SE, Covestro AG, SABIC, DuPont, and Evonik Industries are at the forefront of innovation in the automotive plastics for electrical vehicles market. These companies are developing sustainable and high-performance materials to meet the evolving needs of electric vehicle manufacturers. BASF's focus on sustainable plastics, Covestro's expertise in high-performance materials, SABIC's commitment to eco-friendly solutions, DuPont's broad portfolio of specialty plastics, and Evonik's specialization in high-performance materials collectively drive advancements in the market. Their collaborations with automotive manufacturers and dedication to innovation underscore their significant contributions to the growth of the automotive plastics for electrical vehicles market.

In conclusion, the global automotive plastics for electrical vehicles market is poised for substantial growth driven by the rapid expansion of electric mobility solutions. The segmentation by product type, application, and vehicle type reveals the diverse uses of automotive plastics in electric vehicles, highlighting the importance of lightweight, durable, and sustainable materials in the automotive industry. Market players continue to innovate and collaborate to develop advanced solutions that meet the performance and efficiency requirements of electric vehicles, paving the way for a more sustainable future in the automotive sector.The global automotive plastics for electric vehicles market is witnessing robust growth propelled by the escalating shift towards electric mobility worldwide. As the automotive industry embraces eco-friendly and sustainable solutions, the demand for lightweight, durable, and efficient plastics is on the rise. Key market players such as BASF SE, Covestro AG, SABIC, DuPont, and Evonik Industries are pivotal in driving innovation and advancements in the sector. These companies are not only focusing on developing cutting-edge materials but also collaborating closely with automotive manufacturers to meet the stringent requirements of electric vehicle components.

Polypropylene, polyurethane, PVC, ABS, and polycarbonate are among the prominent plastics utilized in electric vehicles due to their unique properties such as lightweight nature, high strength, resistance to abrasion, and durability. The segmentation by product type showcases the diverse range of materials being employed in different components of electric vehicles, emphasizing the importance of selecting the right plastic for specific applications to enhance functionality and performance.

In terms of applications, the market can be segmented into powertrain, interior, exterior, and other components. Powertrain elements necessitate heat-resistant plastics like polycarbonate and ABS for durability, while interior components leverage lightweight plastics such as polypropylene and PVC for aesthetic appeal and cost-effectiveness. Exterior parts require impact-resistant materials like polyurethane and polyethylene to withstand harsh environmental conditions, indicating the critical role of plastics in ensuring the longevity and efficiency of electric vehicles.

Furthermore, the segmentation by vehicle type underscores the widespread adoption of automotive plastics across passenger cars, commercial vehicles, and electric bikes. With passenger cars leading the surge in demand for electric vehicles, manufacturers are increasingly incorporating advanced materials to meet consumer preferences for sustainable mobility solutions. Commercial vehicles are also embracing automotive plastics to enhance fuel efficiency and comply with stringent environmental regulations, while electric bikes benefit from corrosion-resistant plastics for improved performance and durability.

In conclusion, the global automotive plastics for electric vehicles market presents substantial growth opportunities driven by the escalating trend towards electric mobility and environmental sustainability. Market players' relentless focus on innovation, sustainability, and collaboration with industry stakeholders are shaping the future of automotive plastics, paving the way for a more efficient, eco-friendly, and advanced automotive sector. The strategic utilization of diverse plastics in electric vehicles, coupled with the expertise and technological prowess of leading companies in the market, are poised to revolutionize the automotive industry and propel the transition to a cleaner and more sustainable mode of transportation.

The Automotive Plastics for Electrical Vehicle Market is highly fragmented, featuring intense competition among both global and regional players striving for market share. To explore how global trends are shaping the future of the top 10 companies in the keyword market.

Learn More Now: https://www.databridgemarketresearch.com/reports/global-automotive-plastics-for-electrical-vehicle-market/companies

DBMR Nucleus: Powering Insights, Strategy & Growth

DBMR Nucleus is a dynamic, AI-powered business intelligence platform designed to revolutionize the way organizations access and interpret market data. Developed by Data Bridge Market Research, Nucleus integrates cutting-edge analytics with intuitive dashboards to deliver real-time insights across industries. From tracking market trends and competitive landscapes to uncovering growth opportunities, the platform enables strategic decision-making backed by data-driven evidence. Whether you're a startup or an enterprise, DBMR Nucleus equips you with the tools to stay ahead of the curve and fuel long-term success.

Key Questions Answered in This Report: –

- How has this Automotive Plastics for Electrical Vehicle Marketperformed so far and how will it perform in the coming years?

- Which are the key product types available in this Automotive Plastics for Electrical Vehicle Market?

- Which are the major application areas in theAutomotive Plastics for Electrical Vehicle Market?

- What are the key distribution channels in the global Automotive Plastics for Electrical Vehicle Market?

- What are the key regions in this Automotive Plastics for Electrical Vehicle Market?

- What are the price trends?

- What are the various stages in the value chain of this industry?

- What are the key driving factors and challenges in the market?

Browse More Reports:

About Data Bridge Market Research:

An absolute way to forecast what the future holds is to comprehend the trend today!

Data Bridge Market Research set forth itself as an unconventional and neoteric market research and consulting firm with an unparalleled level of resilience and integrated approaches. We are determined to unearth the best market opportunities and foster efficient information for your business to thrive in the market. Data Bridge endeavors to provide appropriate solutions to the complex business challenges and initiates an effortless decision-making process. Data Bridge is an aftermath of sheer wisdom and experience which was formulated and framed in the year 2015 in Pune.

Contact Us:

Data Bridge Market Research

US: +1 614 591 3140

UK: +44 845 154 9652

APAC : +653 1251 975

Email:- corporatesales@databridgemarketresearch.com

"