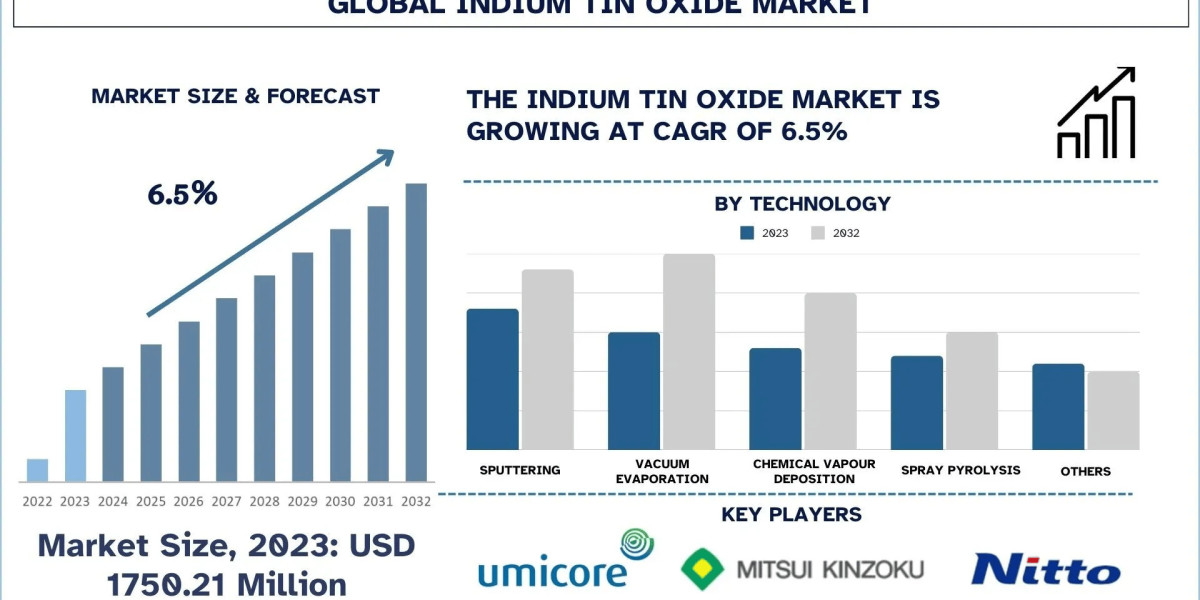

According to the Univdatos, increasing demand for touchscreens, displays, and smart devices, along with the rising adoption of solar panels and OLED technology, are driving the growth of the Indium tin oxide market worldwide. As per their “Indium tin oxide Market” report, the global market was valued at USD 1750.21 million in 2023, growing at a CAGR of about 6.5% during the forecast period from 2024 - 2032 to reach USD million by 2032.

Indium tin oxide (ITO, or tin-doped indium oxide) is a mixture of indium(III) oxide (In2O3) and tin(IV) oxide (SnO2), typically 90% In2O3, 10% SnO2 by weight. In powder form, indium tin oxide (ITO) is yellow-green in color, but it is transparent and colorless when deposited as a thin film at thicknesses of 1000-3000 angstroms. When deposited as a thin film on glass or clear plastic, it functions as a transparent electrical conductor. ITO is normally deposited by a physical vapor deposition process such as D.C. magnetron sputtering or electron beam deposition. Less frequently, ITO can be incorporated in inks using an appropriate film-forming polymer resin and solvent system and deposited by screen printing - albeit with lower transparency and conductivity compared to a physical deposition process. Of the various transparent conductive oxides (TCOs), ITO is considered the premium TCO, having superior conductivity and transparency, stability, and ease of patterning to form transparent circuitry. ITO is used in a number of display technologies, such as LCD, OLED, plasma, electroluminescent, and electro chromatic displays, as well as in a number of touch screen technologies. Further uses of this versatile material include antistatic indium tin oxide coatings, EMI shielding, photovoltaic solar cells, aircraft windshields, and freezer case glass for demisting.

1. Shift Toward Flexible & Foldable Screens

Flexibility and foldable screen technology are some of the future trends that will trigger advancement in the Indium Tin Oxide (ITO) market. There is high pressure on manufacturers to produce novel electronics that can combine thin, flexible, and sturdy features suitable for bendable displays. ITO is the preferred conductive material because of its transparency, which is crucial for touch flexible screens. However, disadvantages such as brittleness and the lack of flexibility have brought constant issues in the stability of ITO coatings, leading to the development of new materials with higher characteristics. New generation foldable smartphones and wearable devices are constantly evolving, and ITO manufacturers are actively seeking how to develop adaptable screen types in response to these dynamic form factors. Thus, future trends and increases in the demand for thin film materials for various applications, including ultra-thin, flexible, and transparent electrodes, ITO’s market will remain lucrative and stable in the forecasted period.

2. Rising Demand for Sustainable and Recyclable Materials

In the ITO market, sustainability issues are becoming critical as versatile and eco-friendly materials are becoming more popular. Thus, the manufacture of ITO depends on the rare and expensive element called indium, due to which producers try to minimize losses and improve the recycling of materials. The proper recycling of indium from old LCDs, solar modules, and consumer electronics is gradually becoming popular as various industries aim for the circular economy. Moreover, the current regulatory requirements in the manufacturing industry and environmental legislations are increasingly forcing manufacturing industries towards using less energy and less waste in the production process of ITO coatings. As industries look for better materials in terms of resource efficiency, efforts are being made to incorporate ITO with graphene or silver nanowires. Moreover, going green has played a vital role in making manufacturing less dependent on resources that will soon become scarce, leading to innovation in the ITO market as well as huge investment opportunities for organizations.

Access sample report (including graphs, charts, and figures)- https://univdatos.com/reports/indium-tin-oxide-market?popup=report-enquiry

3. Increased Focus on High-Resolution Display Technologies

The emerging high-resolution markets like 4K, 8K, and micro-LED panels have emerged to be a major future market trend in the ITO sector. Currently, consumers look for products whose screens are brighter, clearer, and more sensitive to touch, thus encouraging the manufacturing of display layers with better quality, in which ITO plays a major role. ITO is vital in determining the efficiency and high-level performance in televisions, games monitors, and other screens of ultra-high definition. Also, the advancement of augmented reality (AR) and virtual reality (VR) that involve high-resolution devices is increasing the ITO demand. With the display technology constantly advancing, several enhancements of ITO coatings are being created to support the new display technology needs, such as better conductivity and less reflection. The latest designs of mobile phones and tablets with no bezels, slim form factors, and curved displays also place a big emphasis on highly efficient Transparent conducting oxides (TCO) materials, making ITO an important factor in the future development of displays. Out of the high-performance ITO solution providers, the manufacturers are expected to benefit much more from the ever-growing high-resolution display market.

Conclusion

The market for Indium tin oxide is set to grow because of ongoing trend situations like the shift toward flexible & foldable screens, rising demand for sustainable and recyclable materials, and increased focus on high-resolution display technologies worldwide. These trends are accelerating the Indium tin oxide market globally and promoting the development of innovative technologies to obtain the high potential ITO materials.

Contact Us:

Email - contact@univdatos.com

Website - www.univdatos.com