Executive Summary

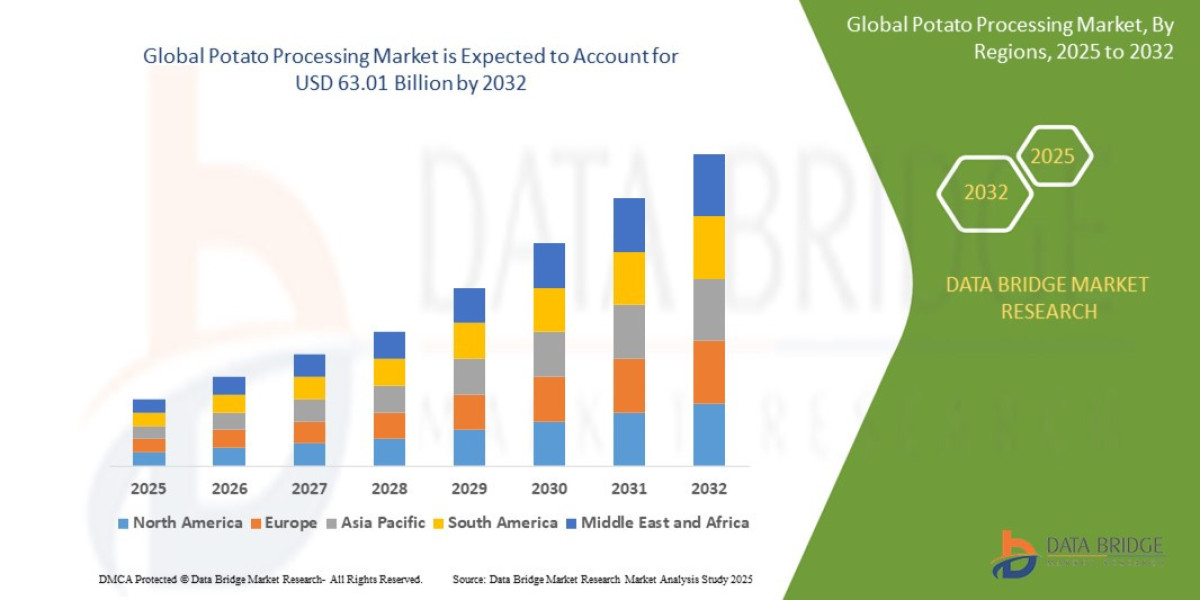

- The global potato processing market size was valued at USD 42.97 billion in 2024 and is expected to reach USD 63.01 billion by 2032, at a CAGR of 4.90% during the forecast period

Market Overview

Definition and Segmentation

The Potato Processing Market covers the commercial transformation of raw potatoes into shelf-stable or ready-to-consume food and industrial products. The market is primarily segmented based on the end-product type:

Frozen Products (Dominant Segment): Includes pre-fried and par-fried products such as french fries, wedges, hash browns, and formed potato products. This segment is the largest in terms of volume and value due to massive demand from institutional buyers (QSRs, hotels, catering).

Chips and Snacks (Retail Segment): Includes traditional potato chips, crisps, and extruded/fabricated potato snacks. This segment is highly consumer-driven, focusing on flavor innovation and healthier formulations.

Dehydrated Products: Includes potato flakes, granules, powder, and flour used primarily in home cooking (mashed potatoes), bakery, and as binding agents in processed foods.

Starches and Derivatives (Industrial Segment): Includes native starch, modified starch (e.g., cationic, pregelatinized), and high-purity potato protein. These are critical functional ingredients in food, textiles, paper, and pharmaceutical industries.

Drivers and Current Dynamics

QSR Industry Expansion: The single most powerful driver is the explosive global growth of QSR chains (McDonald's, Burger King, KFC). French fries are a non-negotiable menu item, guaranteeing predictable, high-volume, global demand for frozen processed potato products.

Increasing Urbanization and Convenience: Rising urban populations and dual-income households increase the demand for convenient, time-saving food solutions, favoring frozen, dehydrated, and ready-to-eat snack formats.

Technological Advancement in Processing: Innovations in peeling, cutting, frying, and freezing technologies (e.g., Individual Quick Freezing - IQF) minimize waste, enhance product quality (texture, color), and improve energy efficiency, supporting mass production.

Functional Ingredient Demand: Potato starch and, increasingly, potato protein, are highly valued for their superior emulsification, gelling, and thickening properties compared to cereal starches, driving growth in the high-margin industrial segment.

Market Size & Forecast

- The global potato processing market size was valued at USD 42.97 billion in 2024 and is expected to reach USD 63.01 billion by 2032, at a CAGR of 4.90% during the forecast period

For More Information Visit https://www.databridgemarketresearch.com/reports/global-potato-processing-market

Key Trends & Innovations

Innovation in potato processing is centered on health perception, waste reduction, and the extraction of high-value co-products.

1. The Pursuit of "Better-for-You" Products

Consumer health trends exert significant pressure on processors, particularly in the chips and frozen segments. Key innovations include:

Low-Acrylamide Technology: New frying and processing techniques (e.g., vacuum frying, lower-temperature finishing) are being deployed to meet tightening regulations concerning acrylamide formation (a potential carcinogen) in fried potatoes.

Reduced Oil Absorption: Utilizing proprietary coatings (often starch- or hydrocolloid-based) applied to french fries before freezing to reduce oil uptake during final preparation.

Air-Fried and Baked Alternatives: Expansion of product lines to offer baked fries, air-fried chips, and kettle-cooked chips that appeal to the clean-label and lower-fat demographics.

2. Valorization of Potato By-products

Historically, potato peelings and residual water were costly waste streams. Today, innovation focuses on the valorization of these materials:

High-Purity Potato Protein: Utilizing advanced membrane filtration and separation techniques to extract high-quality, complete potato protein from starch wastewater. This protein is gaining traction as a premium functional ingredient in dairy alternatives and sports nutrition due to its superior amino acid profile and solubility.

Dietary Fiber and Feed: Converting peel waste into high-fiber flour or sustainable animal feed ingredients.

3. Advanced Processing Technology

Technological innovation in production machinery drives quality and efficiency:

Optical Sorting and AI: Use of high-speed optical sorters powered by machine vision and AI algorithms to detect and remove defects (green spots, blemishes) with sub-millimeter precision, improving raw material yield and final product quality.

High-Pressure Processing (HPP): Employed in the fresh-cut potato segment to extend shelf life without chemical preservatives or heat, preserving the potato's nutritional value and fresh texture.

Competitive Landscape

The market exhibits a high degree of consolidation, particularly in the frozen segment, where global distribution and agricultural scale are prerequisites for competition.

Major Players and Strategies

Global Leaders (Frozen and Snack): McCain Foods, J.R. Simplot Company, Lamb Weston Holdings, Inc., and The Kraft Heinz Company (via Ore-Ida) dominate the frozen market due to deep contractual ties with QSR chains, massive dedicated potato sourcing programs, and extensive cold-chain infrastructure. PepsiCo (Frito-Lay) is the undisputed global leader in the snack chip segment.

Starch and Ingredient Specialists: Companies like Ingredion, Emsland Group, and Cargill focus on the functional ingredient side, competing on product purity, modification capabilities (developing bespoke starches for specific client needs), and the extraction of novel components like potato protein.

Key Competitive Strategies

Backward Integration and Raw Material Control: The ability to secure consistent supply of specific potato varieties (e.g., Russet Burbank for fries, specific high-solids potatoes for chips) through proprietary farming networks or long-term contracts is essential. Price stability depends on this control.

Global Supply Chain Resilience: Developing a network of processing plants geographically distributed across key sourcing regions (North America, Europe, China) mitigates geopolitical risk and optimizes logistics for global QSR distribution.

Clean Label Innovation: In the snack category, competition is driven by innovation in flavor profiles combined with perceived health benefits (e.g., lower sodium, natural coloring, non-GMO status).

Strategic M&A: Ingredient specialists often acquire smaller, innovative firms with proprietary protein extraction or starch modification patents to quickly expand their functional ingredient portfolio.

Regional Insights

North America (NA) and Europe (EU)

These are mature, high-value markets characterized by high per-capita consumption of frozen fries and snack chips. Growth here is slow but highly profitable, driven primarily by premiumization, healthier product launches, and the consistent, high-volume demand from established QSR networks. The EU, in particular, drives regulatory change regarding acrylamide levels, forcing innovation.

Asia-Pacific (APAC)

APAC is the primary engine for future volume growth. Rapid economic growth, rising disposable income, and the aggressive penetration of Western QSR and fast-food culture, particularly in China and India, are fueling demand. The challenge is the necessary build-out of modern cold-chain logistics, which is occurring rapidly and opening up massive market opportunities for frozen product distributors.

Latin America (LATAM) and Middle East & Africa (MEA)

LATAM is a rapidly growing market, offering significant agricultural sourcing opportunities, particularly in countries like Brazil and Argentina. MEA is a burgeoning market for snacks and frozen products, fueled by urbanization and younger demographics. Growth here depends heavily on successful local partnerships and navigating trade barriers.

Challenges & Risks

1. Commodity Price Volatility and Climate Risk

Potato yields are highly sensitive to climate change, including drought and extreme weather events. This volatility directly impacts the raw material cost for processors, necessitating sophisticated hedging and large-scale, diversified sourcing strategies.

2. Health Perception and Regulatory Scrutiny

The processed potato industry faces an enduring challenge regarding the negative health perception associated with fried products (high fat, high sodium). Regulatory bodies, especially in the EU, are increasing scrutiny on harmful by-products like acrylamide, forcing costly process modifications.

3. High Energy and Water Footprint

Potato processing—particularly peeling, blanching, frying, and freezing—is highly energy- and water-intensive. Rising energy costs and increasing environmental compliance pressures pose significant operational risks, mandating substantial capital investment in sustainability technologies.

4. Supply Chain Specialization

The requirement for specific potato varieties for specific products (e.g., high-solids potatoes for fries) means that processors are locked into specialized agricultural supply chains, creating vulnerability if specific regional crops fail.

Opportunities & Strategic Recommendations

Stakeholder Group | Strategic Recommendation | Rationale |

|---|---|---|

Frozen Product Manufacturers | Invest in Global Cold Chain Infrastructure. Target greenfield or acquisition opportunities in Tier 2 and Tier 3 cities across APAC and LATAM to control the supply chain to emerging QSR franchises. | This captures the high-volume growth in emerging markets before the market fully matures, securing first-mover advantage in distribution. |

Ingredient & Starch Specialists | Monetize Potato Protein Isolates. Scale up extraction capabilities for high-purity potato protein, positioning it as a premium, functional, non-allergen alternative to dairy and soy protein in the plant-based sector. | Shifts focus from a low-margin commodity (starch) to a high-margin functional ingredient, diversifying revenue streams dramatically. |

Investors & Venture Capital | Target Green Processing Technology. Focus investment on startups specializing in energy-efficient processing (e.g., advanced heat recovery systems) or sustainable waste-to-value solutions (e.g., potato peel biorefineries). | Addresses the critical risks of high operational costs and environmental compliance, offering high returns via B2B licensing or integration. |

Snack Chip Manufacturers | Aggressively Market Non-Fried Formats. Dedicate significant shelf space and marketing budget to air-fried, baked, or kettle-cooked "better-for-you" chips. | Directly tackles negative health perception, capturing the premium consumer segment willing to pay more for perceived health attributes. |

Agricultural Stakeholders | Develop Climate-Resilient Cultivars. Invest in R&D for potato varieties that are drought-resistant, have naturally low reducing sugar content (to reduce acrylamide risk), and offer higher yield stability. | Secures the foundational raw material supply chain against climate change and minimizes regulatory compliance costs for processors. |

Browse More Reports:

Global Intelligent Power Distribution Unit (PDU) Market

North America Surgical Power Tools Market

Global Non-Invasive Cancer Diagnostics Market

Global Cerebral Vasospasm Market

Middle East and Africa Diet and Nutrition Apps Market

Asia-Pacific Polyimide Films Market

Global Offshore Drilling Market

Global Paragonimiasis Treatment Market

Middle East and Africa Surgical Power tools Market

Europe Sustainable Aviation Fuel Market

Global Cardiovascular Ultrasound System Market

Global Uterine Polyps Drug Market

Global Dental Consumables Market

Global Amusement Parks Market

Global Polyurethane Additives Market

Global Bottled Cocktail Market

Global Self-Adhesive Tear Tape Market

Global Nursing and Residential Care Market

Global Titanium Dioxide Market

Europe Biopreservation Market

Asia-Pacific Personal Care Ingredients Market

Global Yeast Infection Market

Asia-Pacific Unmanned Ground Vehicle Market

Global Shale Gas Processing Equipment Market

Global Veterinary Blood Lactate Test Meter Equipment Market

Asia-Pacific Commercial Cleaning Equipment Market

Asia-Pacific Retail Analytics Market

Europe Weight Loss and Obesity Management Market

North America Biopreservation Market

Global Automotive Emission Test Equipment Market

North America Hydrographic Survey Equipment Market

Global Modular Liquid Crystal Polymer (LCP) Connectors Market

About Data Bridge Market Research:

An absolute way to forecast what the future holds is to comprehend the trend today!

Data Bridge Market Research set forth itself as an unconventional and neoteric market research and consulting firm with an unparalleled level of resilience and integrated approaches. We are determined to unearth the best market opportunities and foster efficient information for your business to thrive in the market. Data Bridge endeavors to provide appropriate solutions to the complex business challenges and initiates an effortless decision-making process. Data Bridge is an aftermath of sheer wisdom and experience which was formulated and framed in the year 2015 in Pune.

Contact Us:

Data Bridge Market Research

US: +1 614 591 3140

UK: +44 845 154 9652

APAC : +653 1251 975

Email:- corporatesales@databridgemarketresearch.com