Executive Summary

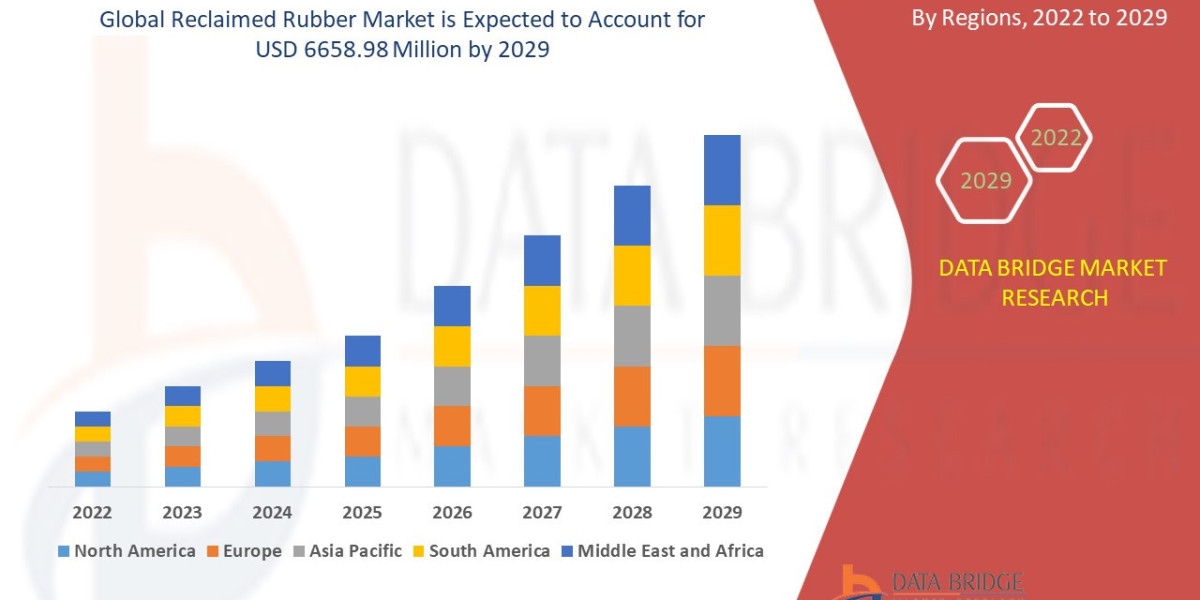

Global Reclaimed Rubber Market was valued at USD 2931.50 million in 2021 and is expected to reach USD 6658.98 million by 2029, registering a CAGR of 10.80% during the forecast period of 2022-2029.

Market Overview

Definition and Process

Reclaimed rubber, or "reclaim," is produced by treating vulcanized rubber scrap (where the polymer chains are chemically cross-linked) to break the sulfur cross-links and partially restore the material’s plasticity. This process, known as devulcanization, allows the material to be compounded and re-vulcanized, often replacing up to 50% of the virgin rubber content in non-critical components.

Key Market Segments by Source Material

Whole Tire Reclaim (WTR) (Dominant Segment): Sourced from scrap passenger and truck tires. This is the highest volume segment, mainly used in tire inner tubes, side walls, mats, and moulded goods.

Butyl Reclaim: Derived from butyl rubber inner tubes. Highly valued for its low gas permeability, making it critical for specialized applications like curing bladders and protective linings.

Ethylene Propylene Diene Monomer (EPDM) Reclaim: Used in weather-stripping, seals, and wire insulation. This segment commands a high price due to its excellent resistance to ozone and heat.

Natural Rubber (NR) and Synthetic Rubber (SR) Specific Reclaims: Specialized reclaims derived from specific industrial waste streams to maintain targeted performance properties.

Key Market Segments by End-Use Application

Automotive and Transportation (Largest Share): Includes inner tubes, mud flaps, floor mats, engine mounts (blends), and non-tread tire compounds.

Footwear: Used extensively in shoe soles, heel blocks, and protective boot construction due to excellent abrasion resistance and cost efficiency.

Building and Construction: Utilized in roofing sheets, membranes, railway pads, and noise/vibration dampening materials.

Industrial Goods: Gaskets, conveyor belts, hoses, and general moulded rubber products.

Drivers and Current Dynamics

ELT Waste Crisis: Globally, billions of tires reach end-of-life annually, posing a severe environmental and fire hazard. Regulatory pressure (e.g., Extended Producer Responsibility - EPR) mandates high recovery rates, directly feeding the reclaim market.

Raw Material Price Volatility: Natural rubber prices are subject to weather, geopolitical instability, and plantation cycles. Reclaimed rubber provides a stable, predictable, and low-cost buffer against this volatility.

Corporate Sustainability Targets: Major $\text{OEM}$s, particularly in the tire and automotive sectors, are setting aggressive, public targets for the use of sustainable and circular materials, legitimizing and institutionalizing the demand for high-quality reclaim.

Cost-Effectiveness: Reclaimed rubber often trades at a significant discount to virgin material, offering manufacturers a substantial advantage in cost-sensitive, high-volume markets.

Market Size & Forecast

Global Reclaimed Rubber Market was valued at USD 2931.50 million in 2021 and is expected to reach USD 6658.98 million by 2029, registering a CAGR of 10.80% during the forecast period of 2022-2029.

For More Information visit https://www.databridgemarketresearch.com/reports/global-reclaimed-rubber-market

Key Trends & Innovations

The future of the reclaimed rubber market hinges on technology that can deliver performance parity with virgin materials.

1. Advanced Devulcanization Technologies

Traditional reclaiming processes (e.g., pan and mechanical methods) often severely degrade the polymer backbone, leading to inferior product. Modern innovation focuses on selective cross-link cleavage:

Microwave Devulcanization: Uses controlled microwave energy to break sulfur bonds more selectively, resulting in a cleaner product with better mechanical properties.

Chemical/Additive Devulcanization: Utilizes specific chemical agents (de-linkers) and high-shear mixers to target the cross-links, offering the highest potential for retaining polymer integrity.

Supercritical CO2: A promising, highly selective method using supercritical carbon dioxide to swell the rubber matrix, aiding chemical action while minimizing heat damage.

2. The Rise of High-Value Pyrolysis Co-existence

A competing ELT pathway, pyrolysis (heating scrap tires in an inert atmosphere), produces Recovered Carbon Black (rCB) and Tire Pyrolysis Oil (TPO). While competing for feedstock, the trend is moving toward integrated circular models where high-purity rCB is used alongside high-quality reclaim to maximize the value derived from the ELT input.

3. Specialty and Purity Focus

Manufacturers are specializing in specific, high-purity reclaims (e.g., Butyl from inner tubes) that yield higher margins and appeal to $\text{OEM}$s. The ability to guarantee the original polymer type of the feedstock is becoming a critical competitive advantage.

4. Digitalization of Feedstock Sorting

The quality of reclaim is only as good as the purity of the scrap input. Innovations in AI-driven sorting and separation technologies (e.g., using near-infrared spectroscopy) are improving the purity of shredded ELT feedstock, drastically reducing contamination that affects the final reclaim’s performance.

Competitive Landscape

The reclaimed rubber market is highly fragmented, with strong regional leaders controlling local waste streams and manufacturing capacity. Global presence is less about single, centralized production and more about establishing regional processing hubs close to both the scrap source and the end-user.

Major Players and Competitive Strategies

Indian and Chinese Manufacturers (Volume Leaders): Companies like Orient Rubber Products (India), GRP Ltd. (India), and various large Chinese reclaimers dominate the market by volume and low-cost production. Their primary strategy is Cost Leadership and securing massive, local ELT collection contracts.

Specialty/Technology-Focused Firms (Quality Leaders): Smaller firms, often in Europe and North America, focusing on advanced chemical or microwave devulcanization. Their strategy is Product Differentiation, targeting Tier 1 $\text{OEM}$s willing to pay a premium for high-performance reclaim to meet sustainability mandates.

Integrated Tire $\text{OEM}$s (Emerging Competitors): Major tire manufacturers (e.g., Bridgestone, Michelin, Goodyear) are increasingly investing in or partnering with reclaimers to vertically integrate their circular supply chain. This is a crucial move to guarantee the quality and volume necessary to meet their own sustainability pledges.

Key Competitive Strategies

Feedstock Acquisition: Controlling the local flow of $\text{ELT}$s is the paramount competitive factor, requiring strong government and municipal partnerships.

Product Consistency: Implementing rigorous testing and quality control (QC) to ensure batch-to-batch consistency, addressing OEM concerns about material reliability.

Certification and Transparency: Gaining third-party certifications (e.g., ISCC Plus for mass balance) to provide verifiable proof of recycled content and traceability for discerning global brands.

Regional Insights

Asia-Pacific (APAC)

Production and Consumption Dominance. APAC holds the largest market share due to its massive, low-cost tire manufacturing base (China, India) and relatively lax environmental regulations that historically favored the low-cost reclamation process. India and China are both the largest producers and consumers of reclaim, using it heavily in footwear, two-wheeler tires, and moulded goods.

North America (NA)

Regulatory-Driven Quality Demand. The NA market is driven by environmental disposal fees and OEM sustainability mandates. The focus is increasingly on high-quality, high-tech reclaim and the competing rCB market. Tire $\text{OEM}$s are actively seeking North American suppliers to localize their supply chains.

Europe

The Circular Economy Leader. EU regulations (e.g., EPR and the Green Deal) provide the strongest market pull for certified sustainable materials. European demand focuses on high-grade EPDM and WTR for use in construction, automotive seals, and infrastructure (e.g., railway pads), where quality standards are high and traceability is essential.

Challenges & Risks

1. Performance Degradation and Consistency

The fundamental challenge remains: no commercial devulcanization process fully restores the material to its virgin state. Reclaim exhibits reduced tensile strength, tear resistance, and elongation compared to virgin rubber, limiting its use in high-dynamic applications (e.g., tire treads). The inherent variability of ELT feedstock further exacerbates consistency issues.

2. Competition from rCB and Pyrolysis

Pyrolysis technology for ELT is rapidly advancing, with rCB gaining traction as a high-value substitute for virgin carbon black. This creates intense feedstock competition with the reclaim sector, potentially driving up the acquisition cost of scrap tires and shrinking the supply available for lower-margin reclaim production.

3. Energy Intensity and ESG Paradox

Traditional devulcanization methods are highly energy-intensive, requiring substantial heat and pressure. This high energy footprint can undermine the sustainability claims of reclaimed rubber, presenting an ESG paradox that advanced technologies (microwave, chemical) are attempting to resolve.

4. Contaminant Risk

Residual contaminants (metals, fibers, incompatible polymers) from poorly sorted $\text{ELT}$s can severely compromise the performance of the final compounded product, leading to rejection by quality-sensitive $\text{OEM}$s.

Opportunities & Strategic Recommendations

Stakeholder Group | Strategic Recommendation | Rationale |

|---|---|---|

Reclaim Manufacturers | Invest in Chemical Devulcanization and Specialization. Shift CapEx away from traditional thermal methods toward chemical or microwave processes to demonstrably improve mechanical properties and create specialized, high-ppurity reclaimed rubber products (e.g., Butyl). | Allows penetration into high-value automotive and sealing segments, justifying a higher price point and differentiating from low-cost WTR suppliers. |

Tire $\text{OEM}$s | Co-locate and Co-Develop Reclaim Facilities with Suppliers. Form strategic joint ventures or long-term partnerships with advanced reclaimers, providing technical expertise and guaranteed off-take agreements tied to specific quality metrics. | Secures a long-term, verifiable supply of high-grade reclaimed material necessary to meet public sustainability commitments without compromising product safety or performance. |

Chemical/Additive Suppliers | Develop Selective De-Vulcanizing Agents. Focus R&D on proprietary, low-energy chemical additives that selectively cleave the sulfur cross-links in the vulcanized matrix without degrading the polymer backbone. | Offers the highest potential for low-energy, high-quality material restoration, solving the industry's central technical bottleneck and creating a high-margin specialty chemical line. |

Investors & Venture Capital | Target ELT Collection and Sorting Tech. Invest in logistics, AI-driven sorting, and separation technologies that can guarantee a clean, homogenous feedstock of specific rubber types (e.g., 99% NR scrap). | The greatest leverage point for improving final reclaim quality is at the beginning of the supply chain (feedstock purity). |

Industrial Goods Manufacturers | Mandate Reclaimed Rubber in Non-Dynamic Parts. Systematically replace 20% to 50% of virgin rubber with certified reclaim in high-volume, static or semi-dynamic parts (e.g., sound dampeners, gaskets, mud flaps). | Immediate, large-scale cost savings and rapid achievement of internal circularity targets with minimal risk to product safety or regulatory compliance. |

Browse More Reports:

North America Data Integration Market

Middle East and Africa Small Molecule Sterile Injectable Drugs Market

Global Rail Fasteners Market

Global Monoterpenes Market

Global Point of Care Infectious Disease Market

Global Canned Berries Market

Global Immunomodulators Market

Global Cancer Gene Therapy Market

Global Solar Thermal Collector Market

Global Freeze-Dried Fruits Market

Global Network Security Software Market

Asia-Pacific Mass Notification Systems Market

Europe Dental Practice Management Software Market

Global Fractional Flow Reserve Market

Global Angiographic Catheter Market

Europe Heavy Metals Testing Market

North America Hand Holes Market

North America Indium Market

Global Skin Packaging Market

Global 3D Cell Culture Market

Global Micro Battery Market

Global Chitosan Market

Global Form-Fill-Seal (FFS) Films Market

Europe Surgical Power Tools Market

Middle East and Africa Flight Data Recorder Market

Global Transthyretin Amyloidosis Treatment Market

Global Flexographic Inks Market

Asia-Pacific Composite Bearings Market

Europe Feed Flavors and Sweeteners Market

Global Interventional Oncology Devices Market

Middle East and Africa Methylene Diphenyl Diisocyanate (MDI) Toluene Diisocyanate (TDI) and Polyurethane Market

Global Weatherproof Camera Market

About Data Bridge Market Research:

An absolute way to forecast what the future holds is to comprehend the trend today!

Data Bridge Market Research set forth itself as an unconventional and neoteric market research and consulting firm with an unparalleled level of resilience and integrated approaches. We are determined to unearth the best market opportunities and foster efficient information for your business to thrive in the market. Data Bridge endeavors to provide appropriate solutions to the complex business challenges and initiates an effortless decision-making process. Data Bridge is an aftermath of sheer wisdom and experience which was formulated and framed in the year 2015 in Pune.

Contact Us:

Data Bridge Market Research

US: +1 614 591 3140

UK: +44 845 154 9652

APAC : +653 1251 975

Email:- corporatesales@databridgemarketresearch.com

"