Executive Summary

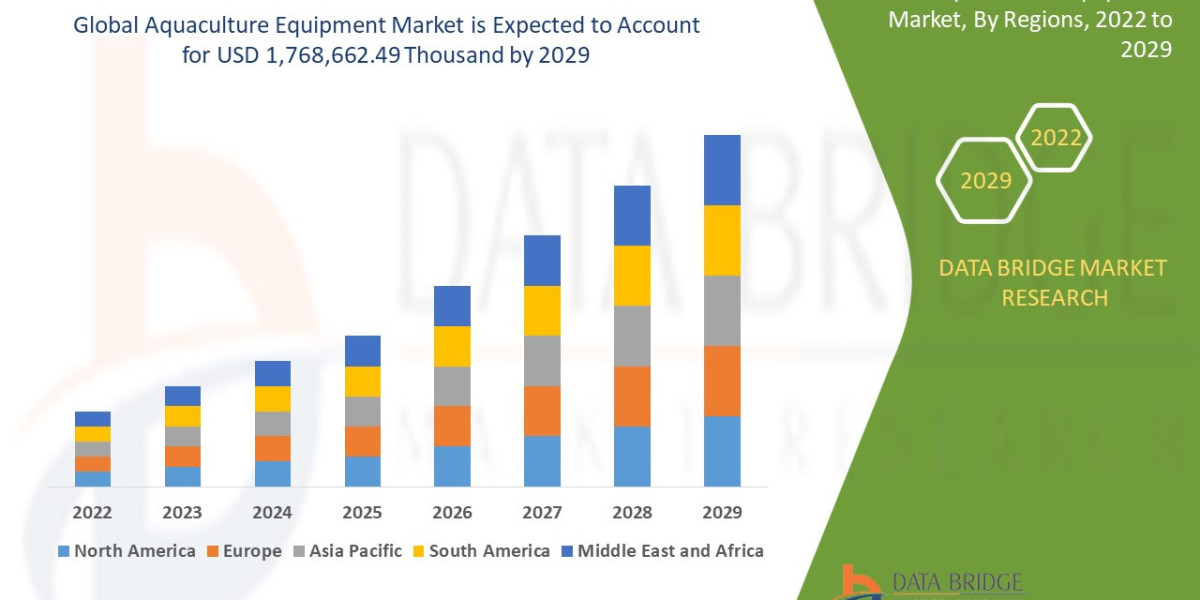

- The global aquaculture equipment market was valued at USD 1.44 billion in 2024 and is expected to reach USD 1.99 billion by 2032

- During the forecast period of 2025 to 2032 the market is likely to grow at a CAGR of 4.10%,

Market Overview

Definition and Core Function

The Aquaculture Equipment Market includes all physical components and integrated technology used in the farming of aquatic organisms. The primary goal of this equipment is to control the aquatic environment (water quality, temperature, dissolved oxygen) and streamline operational efficiency (feeding, cleaning, harvesting) to ensure optimal health and growth of the farmed species.

Key Segments by System Type

Marine and Open-Net Cages (Largest Volume): Traditional and still dominant, utilizing plastic or steel cages anchored in coastal or near-shore marine environments. Equipment includes moorings, nets, anti-predator systems, and remote monitoring buoys.

Recirculating Aquaculture Systems ($\text{RAS}$) (Highest Growth): Land-based, closed-containment systems that filter and reuse up to $99\%$ of the water. Key equipment includes advanced biological and mechanical filtration, oxygenation systems, specialized pumps, and ultraviolet ($\text{UV}$) sterilization units.

Pond and Raceway Systems: Used primarily for carp, shrimp, and tilapia. Equipment focuses on aeration devices (blowers and paddlewheel aerators) and water exchange infrastructure.

Offshore/Deep Sea Aquaculture: Large, semi-submersible cages or closed-containment structures deployed far from the coast in high-energy environments. Requires highly durable materials, sophisticated anchoring, and autonomous monitoring systems.

Key Segments by Equipment Type

Feeding Equipment (Dominant): Automated feeders, feed barges, and centralized feed management systems, often integrated with sensors for precision feeding.

Water Quality Management: Filters ($\text{MBBR}$, drum filters), oxygen generators, ozone ($\text{O}_3$) and $\text{UV}$ disinfection units, and sensors ($\text{DO}$, $\text{pH}$, temperature).

Netting and Containment: $\text{HDPE}$ cages, submersible cages, specialized netting materials (copper alloy/steel mesh for anti-fouling), and mooring systems.

Harvesting and Processing: Fish pumps, grading machines, and ice/chilling equipment.

Drivers and Current Dynamics

Depleting Wild Fisheries: The $\text{FAO}$ reports that over $34\%$ of the world's fisheries are biologically unsustainable, creating a hard ceiling on wild catch and permanently shifting protein demand to aquaculture.

Food Security and Demand: Global seafood consumption continues to rise, especially in $\text{APAC}$. Aquaculture is essential for bridging the gap between supply and demand.

Disease Mitigation and Environmental $\text{ESG}$ Pressure: Concerns over disease transfer, nutrient effluent (pollution), and escapees from traditional net pens are driving regulatory pressure toward environmentally controlled solutions ($\text{RAS}$ and Offshore), which require high-tech equipment.

Automation for Efficiency: Rising labor costs, particularly in developed markets, drive the need for autonomous feeding, monitoring, and cleaning solutions to optimize operating expenses ($\text{OpEx}$).

Market Size & Forecast

- The global aquaculture equipment market was valued at USD 1.44 billion in 2024 and is expected to reach USD 1.99 billion by 2032

- During the forecast period of 2025 to 2032 the market is likely to grow at a CAGR of 4.10%,

For More Information Visit https://www.databridgemarketresearch.com/reports/global-aquaculture-equipment-market

Key Trends & Innovations

The market is being redefined by digitalization and the shift toward extreme environmental control.

1. Recirculating Aquaculture Systems ($\text{RAS}$) Scale-Up

$\text{RAS}$ is the defining trend. Companies are building facilities capable of producing thousands of tons of fish annually, often located near major consumption centers (e.g., outside large cities in the $\text{US}$ Midwest). Innovation here centers on energy efficiency—specifically reducing the power demand of water pumps and oxygen generation through improved design and $\text{AI}$-driven process control.

2. Offshore and Submersible Farming

As coastal areas become crowded and environmentally sensitive, the industry is moving into deep, exposed offshore waters. This requires highly specialized, robust, and automated equipment:

Semi-submersible Cages: Massive, often steel-reinforced structures capable of lowering themselves below the surface to avoid high-energy storms and surface parasites (sea lice).

Advanced Mooring Systems: Utilizing dynamic positioning and sophisticated sensor data to maintain stability far from shore.

3. $\text{AI}$ and IoT-Driven Precision Aquaculture

The integration of the Internet of Things ($\text{IoT}$) and $\text{AI}$ is transforming farming practices from reactive to predictive.

Automated Feeding Optimization: Underwater cameras and acoustic sensors monitor fish behavior, appetite, and biomass in real-time. $\text{AI}$ algorithms adjust feed delivery frequency and volume to minimize waste and optimize the Feed Conversion Ratio ($\text{FCR}$), the most critical economic metric.

Remote Health Monitoring: Autonomous underwater vehicles ($\text{AUV}$s) and cameras use image analysis ($\text{AI}$) to detect early signs of disease, lice infestations, or behavioral stress before human operators can spot them.

4. Energy Efficiency and Hybrid Power

The $\text{OpEx}$ of $\text{RAS}$ is often dominated by electricity costs. A major trend is the integration of renewable energy sources, such as floating solar panels on ponds or wind and wave energy generators mounted on offshore platforms, to achieve lower carbon footprints and stabilize operating costs.

Competitive Landscape

The market is led by diversified engineering and industrial equipment giants, but also features highly specialized technology firms focused on water treatment and automation.

Major Players and Strategies

Diversified Industrials (The Integrators): Firms like Akva Group ($\text{Norway}$), Pentair ($\text{US}$), and $\text{Xylem}$ ($\text{US}$). These companies offer comprehensive, turn-key solutions that span consulting, design, and equipment supply for $\text{RAS}$ and advanced marine sites. Their strategy is Service and System Integration, offering proprietary software ($\text{AI}$ monitoring) bundled with hardware.

Netting and Containment Specialists: Companies focused on manufacturing high-strength containment structures (e.g., Garware Technical Fibres ($\text{India}$), Badinotti Group ($\text{Italy}$)). Their strategy is Material Innovation, developing anti-fouling nets and ultra-durable plastic and steel cages to withstand deep-sea environments.

Feed Technology Specialists: Firms dedicated solely to automated feeding and feed barges (e.g., Fjordveid AS ($\text{Norway}$)). Their focus is on Precision and Efficiency, using advanced sensors to minimize feed waste, which is the single largest operating cost.

Key Competitive Strategies

Vertical Integration and Turnkey Solutions: Offering full project lifecycle management—from feasibility studies to operation and maintenance contracts—to simplify complex $\text{RAS}$ and Offshore builds for aquaculture operators.

Strategic $\text{M\&A}$: Larger players are acquiring small, innovative $\text{AI}$ and sensor technology companies to immediately integrate cutting-edge monitoring capabilities, accelerating their digital service offerings.

$\text{ESG}$ and Certification Focus: Positioning equipment (especially $\text{RAS}$ filtration and waste management units) as essential tools for achieving $\text{BAP}$ (Best Aquaculture Practices) or $\text{ASC}$ (Aquaculture Stewardship Council) certification, thereby justifying a price premium.

Regional Insights

Asia-Pacific (APAC)

Market Volume and Pond Dominance. $\text{APAC}$ is the largest market by volume and revenue, driven by countries like China, India, and Vietnam, which dominate shrimp and finfish (tilapia, carp) production. The market here is traditionally low-tech, relying on pond and simple cage systems, with the largest demand for low-cost aeration and feeding equipment. However, high-value markets (Japan, Korea) are seeing rapid adoption of $\text{RAS}$ for land-based Yellowtail and Salmon.

Europe

Technology Leader and $\text{RAS}$ Pioneer. Europe (especially Norway and the $\text{UK}$) is the innovation hub, driven by the massive Salmon industry. Norway is the global leader in both advanced offshore farming infrastructure and $\text{RAS}$ development. The demand is heavily skewed toward high-end water treatment, fish health management, and automation technologies to maintain premium quality in a highly regulated environment.

North America (NA)

Emerging $\text{RAS}$ Powerhouse. The $\text{NA}$ market is characterized by significant investment in large, land-based $\text{RAS}$ facilities, primarily for Atlantic Salmon. Policy support and investment from food conglomerates are creating a strong market for American and European equipment suppliers specializing in filtration and waste treatment to meet strict local environmental discharge rules.

Challenges & Risks

1. High Initial $\text{CapEx}$ for Advanced Systems

The cost to build a commercial-scale $\text{RAS}$ facility can be $5$ to $10$ times higher than a traditional net-pen farm. This massive initial $\text{CapEx}$ deters small and medium enterprises ($\text{SME}$s) and creates significant financial risk, particularly when integrated with unproven, early-stage technologies.

2. Energy Consumption of $\text{RAS}$

While $\text{RAS}$ solves water quality issues, it requires continuous pumping, filtration, and oxygenation, leading to high electricity usage. The failure to secure reliable, cost-effective power can render a project economically unviable, placing pressure on equipment manufacturers to deliver highly efficient components.

3. Bio-Risk and System Failure

Disease outbreaks (especially in high-density $\text{RAS}$ or traditional net pens) remain a core risk. The equipment market is susceptible to rapid shifts in demand if a high-tech system fails (e.g., a pump failure causing immediate loss of oxygen), leading to reputational damage that can slow adoption.

4. Regulatory and Permitting Bottlenecks

Gaining permits for large offshore and land-based $\text{RAS}$ projects is complex and time-consuming, often involving significant local opposition. This uncertainty creates stop-start demand, making it difficult for equipment manufacturers to plan and scale their production lines.

Opportunities & Strategic Recommendations

Stakeholder Group | Strategic Recommendation | Rationale |

|---|---|---|

Equipment Manufacturers | Modularize $\text{RAS}$ Components and Offer $\text{Opex}$-Focused Leasing. Develop standardized, pre-fabricated $\text{RAS}$ modules that can be quickly assembled. Offer equipment leasing models tied to performance or $\text{OpEx}$ savings (e.g., energy consumption). | Reduces the massive $\text{CapEx}$ hurdle for new operators, accelerating adoption and ensuring a recurring revenue stream tied to equipment maintenance and upgrades. |

Technology Startups | Focus on Non-Invasive Waterless Sensors and $\text{AI}$ Diagnostics. Develop solutions that can monitor water chemistry and fish health without relying on physical probes or invasive procedures. Focus on predictive maintenance for mechanical failure points. | Solves the pain points of system downtime and measurement lag, delivering verifiable $\text{OpEx}$ savings and risk reduction that operators are willing to pay a premium for. |

Investors & Private Equity | Target $\text{BAP}$/$\text{ASC}$-Certified Waste Treatment Technology. Invest in firms specializing in sludge dewatering, nutrient recovery, and waste-to-energy systems specifically designed for $\text{RAS}$ output. | Captures the high-growth opportunity in the post-harvest/waste management segment, which is critical for securing the environmental permits necessary for high-value $\text{RAS}$ projects. |

Traditional Cage Manufacturers | Develop Hybrid Closed-Containment Systems (Semi-Closed). Innovate containment structures that combine the flow-through benefits of marine cages with physical barriers and filtration to manage sea lice and effluent, bridging the gap between low-cost and high-tech systems. | Offers a practical, mid-market solution to meet rising environmental demands without requiring the extreme $\text{CapEx}$ of full land-based $\text{RAS}$. |

Governments & Regulatory Bodies | Establish Permitting Fast-Tracks for Certified $\text{RAS}$ Projects. Create streamlined regulatory processes for aquaculture projects that use best-available technology (e.g., $\text{RAS}$) with verified minimal environmental impact. | Provides the policy certainty and speed necessary to encourage large, institutional investment in the domestic aquaculture sector, improving food security. |

Browse More Reports:

Global Mastitis Market

Global Glucocorticoid Agonist Market

Global Ultra-High Barrier Shrink Films Market

North America Sustainable Aviation Fuel Market

North America Lung Cancer Diagnostics Market

Global Cannabidiol (CBD) Infused Edible Market

Global Garage and Service Station Market

Global Physiotherapy Examination Tables Market

Global Composite Bearings Market

Europe Ostomy Devices Market

U.S. Diet and Nutrition Apps Market

Asia- Pacific Plant Based Protein Market

Global Atomic Force Microscope (AFM) Market

Global Sailing Jackets Market

U.S. Electric Enclosure Market

Global Long Fiber Thermoplastics Market

Global Cocoa Processing Equipment Market

Global Medical Tuning Fork Market

Global Modified Bitumen Market

Global Medical Device Cleaning Market

Global Biodetectors and Accessories Market

Global Heavy Metals Testing Market

Global Glucaric Acid Market

Global Ruminant Feed Antibiotics Market

Global Aircraft Thrust Reverser Market

Asia-Pacific Frozen Ready Meals Market

Middle East and Africa Laminated Busbar Market

Global Train Signalling System Market

Global Heat Stabilizers Market

Asia-Pacific Surgical Power Tools Market

North America Frozen Ready Meals Market

Global Cereals & Grains Crop Oil Concentrates Market

About Data Bridge Market Research:

An absolute way to forecast what the future holds is to comprehend the trend today!

Data Bridge Market Research set forth itself as an unconventional and neoteric market research and consulting firm with an unparalleled level of resilience and integrated approaches. We are determined to unearth the best market opportunities and foster efficient information for your business to thrive in the market. Data Bridge endeavors to provide appropriate solutions to the complex business challenges and initiates an effortless decision-making process. Data Bridge is an aftermath of sheer wisdom and experience which was formulated and framed in the year 2015 in Pune.

Contact Us:

Data Bridge Market Research

US: +1 614 591 3140

UK: +44 845 154 9652

APAC : +653 1251 975

Email:- corporatesales@databridgemarketresearch.com